AVIATION AND JET FUEL PRICES JET-A,100LL AND AVGAS

|

|

|

|

|

AIRNAV CURRENT AVIATION FUEL PRICES - Get local fuel prices near your airport. Airport or Zip code: Type(s) of Fuel: Jet A 100LL Avgas.

AVIATION FUEL PRICES BY US REGION - Pilots can view current aviation fuel prices as well as average US and regional aircraft fuel prices.

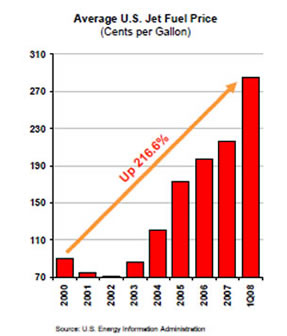

Aviation Jet Fuel Prices and InformationJet fuel is a type of aviation fuel designed for use in aircraft powered by gas-turbine engines. It is clear to straw-colored in appearance. The most commonly used fuels for commercial aviation are Jet A and Jet A-1 which are produced to a standardised international specification. The only other jet fuel commonly used in civilian turbine-engine powered aviation is Jet B which is used for its enhanced cold-weather performance. Jet fuel is a mixture of a large number of different hydrocarbons. The range of their sizes (molecular weights or carbon numbers) is restricted by the requirements for the product, for example, freezing point or smoke point. Kerosene-type jet fuel (including Jet A and Jet A-1) has a carbon number distribution between about 8 and 16 carbon numbers; wide-cut or naphtha-type jet fuel (including Jet B), between about 5 and 15 carbon numbers. History of jet fuel Fuel for a piston-engine powered aircraft (usually a high-octane gasoline known as avgas) has a low flash point to improve its ignition characteristics. Turbine engines can operate with a wide range of fuels, and jet-aircraft engines typically use fuels with higher flash points, which are less flammable and therefore safer to transport and handle. The first jet fuels were based on kerosene or a gasoline-kerosene mix, and most jet fuels are still kerosene-based. Types of Jet Fuel Differences Between Jet A and Jet A-1 The primary differences between Jet A and Jet A-1 are the higher freezing point of Jet A (−40 °C vs −47 °C for Jet A-1), and the mandatory requirement for the addition of an anti-static additive to Jet A-1. Like Jet A-1, Jet A can be identified in trucks and storage facilities by the UN number 1863 Hazardous Material placards. Jet A trucks, storage tanks, and pipes that carry Jet A are marked with a black sticker with a white "Jet A" written over it, next to another black stripe. The annual U.S. usage of jet fuel was 21 billion gallons (80 billion litres) in 2006. Typical Physical Properties for Jet A and Jet A-1 Jet A-1 Fuel must meet the specification for DEF STAN 91-91 (Jet A-1), ASTM specification D1655 (Jet A-1) and IATA Guidance Material (Kerosine Type), NATO Code F-35. Water in jet fuel It is very important that jet fuel is free from water contamination. During a flight the temperature of the fuel in the tanks will decrease due to the low temperatures in the upper atmosphere. This will cause dissolved water in the fuel to precipitate out and since the water is more dense than fuel it will drop to the bottom of the tank. Since it is no longer in solution this water can freeze, blocking fuel inlet pipes. Since it is impractical to remove all water from fuel, fuel heaters are usually used on commercial aircraft to prevent water in the fuel from freezing. There are several methods for detection of water in jet fuel. A visual check may detect high concentrations of suspended water, as this will cause the fuel to become hazy in appearance. An industry standard chemical test for the detection of free water in jet fuel is the Shell Water Detector, having a water-sensitive filter pad that turns blue if the fuel exceeds the specification limit of 30ppm free water. Military jet fuels Military organisations around the world use a different classification system of JP numbers. Some are almost identical to their civilian counterparts and differ only by the amounts of a few additives; Jet A-1 is similar to JP-8, Jet B is similar to JP-4. Other military fuels are highly specialized products and are developed for very specific applications. JP-5 fuel is fairly common, and was introduced to reduce the risk of fire on aircraft carriers (has a higher flash point - a minimum of 60 °C). Other fuels were specific to one type of aircraft. JP-6 was developed specifically for the XB-70 Valkyrie and JP-7 for the SR-71 Blackbird. Both these fuels were engineered to have a high flash point to better cope with the heat and stresses of high speed supersonic flight. One aircraft-specific jet fuel still in use by the United States Air Force is JPTS, which was developed in 1956 for the Lockheed U-2 spy plane. Jet fuels are sometimes classified as kerosene or naphtha-type. Kerosene-type fuels include Jet A, Jet A-1, JP-5 and JP-8. Naphtha-type jet fuels, sometimes referred to as "wide-cut" jet fuel, include Jet B and JP-4. Piston engine use Jet fuel is very similar to diesel fuel, and in some cases, may be burned in diesel engines. The possibility of environmental legislation banning the use of leaded avgas, and the lack of a replacement fuel with similar performance, has left aircraft designers and pilot's organizations searching for alternative engines for use in small aircraft. As a result, a few aircraft engine manufacturers, most notably Thielert, have begun offering diesel aircraft engines which run on jet fuel. This technology has potential to simplify airport logistics by reducing the number of fuel types required. Jet fuel is available in most places in the world, whereas avgas is only widely available in a few countries which have a large number of general aviation aircraft. A diesel engine may also potentially be more environmentally friendly and fuel-efficient than an avgas engine. However, very few diesel aircraft engines have been certified by aviation authorities, and widespread use of diesel aircraft engines is still years in the future. Jet fuel is often used in ground support vehicles at airports, instead of diesel. The United States military makes heavy use of JP-8, for instance. However, jet fuel tends to have poor lubricating ability in comparison to diesel, thereby increasing wear on fuel pumps and other related engine parts. Civilian vehicles tend to disallow its use, or require that an additive be mixed with the jet fuel to restore its lubricity. Since jet fuel is also significantly more expensive than diesel, some critics consider using jet fuel in ground vehicles as wasteful. Synthetic Jet fuel A significant effort is under way to certify Fischer–Tropsch (FT) synthetic fuels for use in U.S. and international aviation fleets. In this effort is being led by an industry coalition known as the Commercial Aviation Alternative Fuels Initiative (CAAFI), also supported by a parallel initiative under way in the U.S. Air Force, to certify FT fuel for use in all aviation platforms. The U.S. Air Force has a stated goal of certifying its entire fleet for use with FT synthetic fuel blends by 2011. The CAAFI initiative aims to certify the civilian aviation fleet for FT synthetic fuels blends by 2010, and has programs under way to certify HRJ hydrogenated biofuels as early as 2013. Synthetic jet fuels show a reduction in pollutants such as SOx, NOx, particulate matter, and hydrocarbon emissions. Jet biofuels The air transport industry is responsible for 2 percent of man-made carbon dioxide emitted. Boeing estimates that biofuels could reduce flight-related greenhouse-gas emissions by 60 to 80 percent. The solution would be blending algae fuels with existing jet fuel Green Flight International became the first airline to fly jet aircraft on 100% biofuel. The flight from Stead airport in Reno, Nevada was in an Aero L-29 Delfín piloted by Carol Sugars and Douglas Rodante. * Boeing and Air New Zealand are collaborating with Tecbio Aquaflow Bionomic and other jet biofuel developers around the world. Oil prices increased about fivefold from 2003 to 2008, raising fears that world petroleum production is becoming unable to keep up with demand. The fact that there are few alternatives to petroleum for aviation fuel adds urgency to the search for alternatives. Twenty-five airlines were bankrupted or stopped operations in the first six months of 2008, largely due to fuel costs. |

Aviation biofuel is a biofuel used for aircraft

Aviation's share of the greenhouse gas emissions is poised to grow, as air travel increases and ground vehicles use more alternative fuels like ethanol and biodiesel. Boeing estimates that biofuels could reduce flight-related greenhouse-gas emissions by 60 to 80 percent. The solution would be blending algae fuels with existing jet fuel. Boeing executives said the company is informally collaborating with leading Brazilian biofuels maker Tecbio, Aquaflow Bionomic of New Zealand and other fuel developers around the world. So far, Boeing has tested six fuels from these companies, and will probably have gone through 20 fuels by the time we're done evaluating them. Boeing is joining other aviation-related members in the Algal Biomass Organization (ABO). The International Air Transport Association (IATA) supports research, development and deployment of algal fuels. IATA’s goal is for its members to be using 10% alternative fuels by 2017. In the effort to develop an aviation biofuel, Air New Zealand and Boeing are researching the jatropha plant to see if it is a sustainable alternative to conventional fuel. A two-hour test flight using a 50-50 mixture of the new biofuel with Jet A-1 in the number one position Rolls Royce RB-211 engine of 747-400 ZK-NBS, was successfully completed on 30 December 2008. The engine was then removed to be scrutinised and studied to identify any differences between the Jatropha blend and regular Jet A1. No effects to performances were found. On January 8, 2009, Continental Airlines ran the first test for the first flight of an algae-fueled jet. The test was done using a twin-engine commercial jet with one engine consuming a 50/50 blend of biofuel and normal aircraft fuel. It was the first flight by a U.S. carrier to use an alternative fuel source on this specific type of aircraft. The flight from Houston's George Bush Intercontinental Airport completed a circuit over the Gulf of Mexico. The pilots on-board, executed a series of tests at 38,000 feet (12,000 m), including a mid-flight engine shutdown. Larry Kellner, chief executive of Continental Airlines, said they had tested a drop-in fuel which meant that no modification to the engine was required. The fuel was praised for having a low flash point and sufficiently low freezing point, issues that have been problematic for other bio-fuels. Japan Airlines conducted a one and a half hour flight with one engine burning a 50/50 mix of Jet-A and biofuel from the Camelina plant. The United States Navy is planning to use biofuel from the Camelina plant for their F/A-18 testing. On March 25, 2010, the United States Air Force conducted the first flight of an aircraft with all engines powered by a biofuel blend. The flight, performed on an A-10 at Eglin Air Force Base, used a 50/50 blend of JP-8 and Camelina-based fuel. |

© AviationExplorer.com - The Website For Aviation Enthusiasts |